In today’s fast-paced industrial environment, maximizing warehouse efficiency is more critical than ever. One of the key components in achieving an optimized storage solution is a robust, reliable heavy duty racking system. Designed to handle large, bulky, and heavy loads, a heavy duty racking system offers a durable and flexible solution that can transform the way warehouses operate. In this article, we will explore what a heavy duty racking system is, its functions, benefits, uses, and tips for proper usage and maintenance. If you’re looking for a storage solution that stands the test of time and delivers exceptional performance, read on to learn how a heavy duty racking system can revolutionize your big warehouse.

What is a Heavy Duty Racking System?

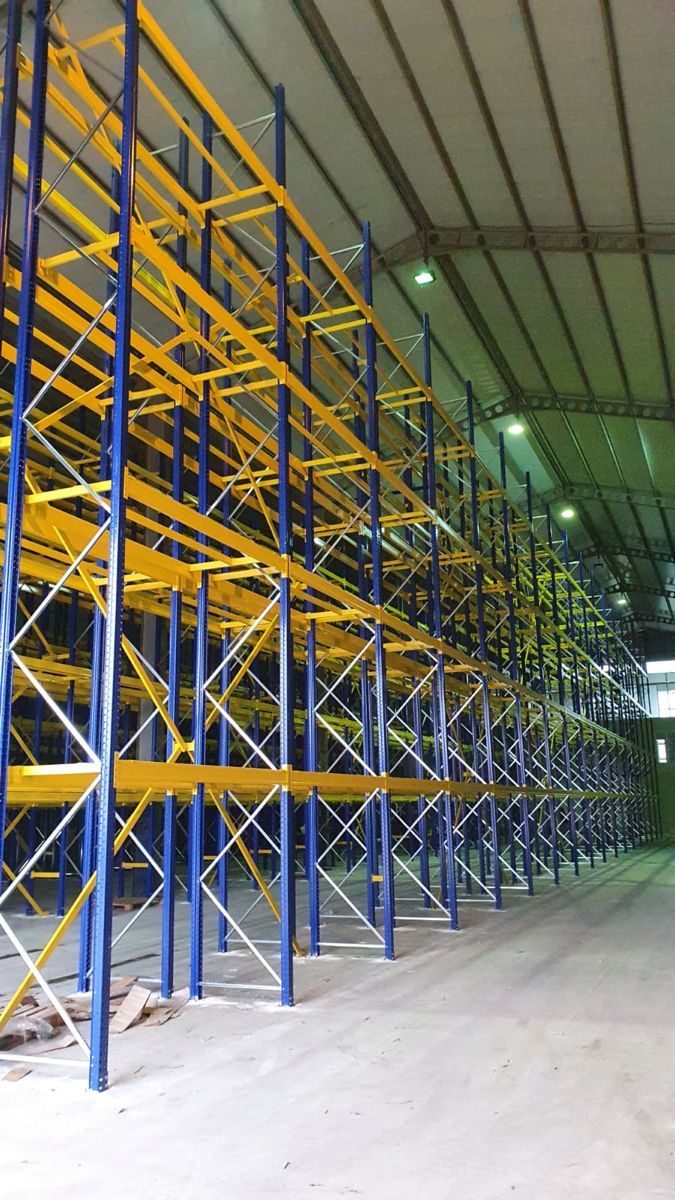

A heavy duty racking system is an advanced storage solution engineered specifically for industrial warehouses that need to store large volumes of heavy goods. Constructed primarily from high-quality steel or cold-rolled steel, these systems are built to endure extreme loads—often several tons per level. Unlike conventional storage systems, heavy duty racks are designed for durability, safety, and optimal space utilization. Their robust construction, modular design, and customizable configurations make them ideal for warehouses that require both capacity and reliability.

Heavy duty racking systems are not only about storing goods; they are about creating an organized, efficient, and safe working environment that supports high productivity and minimizes operational costs.

Functions and Key Features of Heavy Duty Racking System

Heavy duty racking systems serve multiple essential functions in a warehouse setting:

- Optimized Space Utilization:

Heavy duty racking systems maximize the use of vertical space. By stacking goods on multiple levels, warehouses can significantly increase storage capacity without expanding the physical footprint. - Improved Inventory Management:

An organized racking system facilitates easy categorization and retrieval of goods. Items stored on clearly defined levels allow for efficient inventory control and reduce the time required for picking and restocking. - Enhanced Safety and Security:

Designed to withstand heavy loads, these racks ensure that goods remain secure and stable. Their robust construction minimizes the risk of structural failures and accidents, thereby protecting both the inventory and warehouse personnel. - Increased Operational Efficiency:

By streamlining storage and retrieval processes, heavy duty racking systems contribute to faster order fulfillment and improved overall warehouse operations. This efficiency is especially crucial for industries with high throughput demands. - Flexibility and Scalability:

With a modular design, heavy duty racks can be customized to fit the specific needs of a warehouse. Whether you need to modify the number of levels or adjust the dimensions, these systems offer the flexibility to scale up as your business grows.

Key features of heavy duty racking systems include:

- Robust Construction: Premium materials such as high-strength steel ensure durability.

- Customizable Configurations: Adjustable shelves and modular components allow for tailored storage solutions.

- Corrosion Resistance: Powder coating and specialized chemical treatments enhance longevity by protecting against rust and environmental wear.

- Ease of Integration: These systems can be easily integrated with modern warehouse management systems (WMS) and material handling equipment like forklifts.

Benefits of Using a Heavy Duty Racking Systems

Implementing a heavy duty racking system in your warehouse offers a multitude of benefits:

1. Maximized Storage Capacity

By utilizing vertical space efficiently, heavy duty racking systems can dramatically increase the storage capacity of a warehouse. This is particularly advantageous in urban industrial settings where floor space is limited but inventory volumes are high.

2. Enhanced Operational Efficiency

When goods are stored in an organized manner, warehouse staff can quickly locate and retrieve items, reducing downtime and improving throughput. Faster order processing translates to increased customer satisfaction and higher overall productivity.

3. Superior Safety Standards

Heavy duty racks are engineered to meet strict safety standards, ensuring that heavy loads are securely supported. This not only protects your inventory but also minimizes the risk of workplace accidents, leading to a safer environment for employees.

4. Cost-Effective Investment

Although heavy duty racking systems may require a significant initial investment, they offer long-term cost savings. Improved space utilization means you can delay or avoid the costs of expanding your warehouse. Additionally, reduced labor costs and lower maintenance expenses contribute to a favorable return on investment.

5. Versatility Across Industries

Whether you operate in manufacturing, logistics, distribution, retail, or any other industrial sector, heavy duty racking systems can be adapted to your specific needs. Their flexible design and high load capacity make them suitable for a wide range of applications—from storing raw materials and finished products to supporting heavy machinery and industrial components.

Uses of Heavy Duty Racking System in Industrial Warehouses

Heavy duty racking systems have become indispensable in industrial warehouses for various reasons. Here are some common applications:

- Pallet Storage:

One of the most widespread uses of heavy duty racks is for pallet storage. Whether it’s raw materials, finished goods, or components, pallet racking systems enable warehouses to store items efficiently and retrieve them quickly using forklifts. - Bulk Storage:

For industries dealing with large quantities of uniform products, heavy duty racking systems facilitate bulk storage. This is particularly useful in manufacturing and distribution centers where high inventory volumes are common. - Component Storage:

In sectors such as automotive and electronics, where small but heavy components must be stored safely, heavy duty racks provide the necessary strength and organization to keep these items secure and easily accessible. - High-Density Storage:

Warehouses that require high-density storage solutions benefit from heavy duty racks that allow items to be stored at multiple levels without sacrificing accessibility or safety. - Cross-Docking Applications:

In distribution centers, heavy duty racking systems are used in cross-docking operations to streamline the process of receiving, sorting, and dispatching goods efficiently.

Tips for Proper Use and Maintenance of Heavy Duty Racking System

To ensure that your heavy duty racking system operates safely and efficiently, consider the following best practices:

Proper Installation

- Professional Setup: Always have your heavy duty racks installed by certified professionals. Proper installation ensures that the racks can support the maximum load capacity and maintain stability under stress.

- Secure Anchoring: Ensure that all racks are securely anchored to the floor or wall, especially in high-traffic areas. This is vital for preventing movement or collapse.

Adhere to Load Limits

- Respect Capacity Specifications: Never exceed the manufacturer’s load limits per level. Overloading can compromise the structural integrity of the system and lead to potential safety hazards.

- Even Load Distribution: Distribute the weight evenly across the rack to avoid creating pressure points that can weaken the structure over time.

Regular Inspections and Maintenance

- Scheduled Inspections: Perform regular inspections to detect any signs of wear, damage, or corrosion. Address any issues immediately to avoid further damage.

- Routine Cleaning: Keep the racks clean and free from dust, debris, or chemical spills that might lead to corrosion. Regular cleaning also helps maintain the aesthetic appeal of the warehouse.

- Component Replacement: Replace any worn or damaged components, such as bolts, fasteners, or beams, to ensure the system remains robust and safe.

Employee Training

- Safety Protocols: Train warehouse staff on the proper use of heavy duty racks, including safe loading and unloading procedures. Educated employees are key to preventing accidents and maintaining the longevity of the system.

- Operational Guidelines: Provide clear guidelines on how to handle heavy loads and use material handling equipment around the racks. This helps minimize human error and potential damage to the racks.

Planning for Future Expansion

- Modular Design: Choose a heavy duty racking system with a modular design that can be easily expanded or reconfigured as your storage needs grow.

- Scalability: Consider future inventory growth when planning your warehouse layout. A scalable system ensures that you won’t have to overhaul your storage solution as your business expands.

Why Choose RAJA RAK GUDANG INDONESIA?

For over 12 years, RAJA RAK GUDANG INDONESIA has been a trusted provider of high-quality warehouse storage solutions across Indonesia. With a customer base exceeding 20,000 clients and a diverse portfolio of more than 500 types of warehouse and display racks, we are the leading experts in heavy duty racking systems.

Our RAJA RAK GUDANG INDONESIA products are known for their superior strength, durability, and flexibility. We design our racks to meet the stringent demands of industrial warehouses, ensuring that they can handle heavy loads and provide efficient storage solutions. With our expertise and commitment to excellence, we guarantee the best quality and service for your storage needs.

Product Overview: RAK BESI GUDANG PABRIK UKURAN BESAR KAPASITAS 2 TON / LEVEL TIPE RR-2000

Our flagship product, RAK BESI GUDANG PABRIK UKURAN BESAR KAPASITAS 2 TON / LEVEL TIPE RR-2000, is specifically engineered for heavy-duty storage in large industrial warehouses. Here’s what sets it apart:

- Dimensions:

- Height: Ranges from 1000 mm to 12000 mm

- Width: 500 mm to 1500 mm

- Length: 500 mm to 4200 mm

- Load Capacity: 2000 kg (2 Ton) per layer, with typical usage not exceeding 10 Ton per set.

- Layer Configuration: Customizable from 1 to 12 layers.

- Material: Constructed from high-quality cold-rolled steel.

- Finish: Finished with a durable powder coating that resists corrosion and extends product life.

- Accuracy: Dimensions can be customized with precision up to 0.5 mm.

- Accessories: Includes necessary bolts and nuts, with optional accessories such as post covers, post guards, and spacers.

- Customization: Available in a variety of colors and sizes to meet specific customer requirements.

- Designed For: Heavy-duty storage of industrial cargo, large machinery parts, raw materials, and more.\n\nThe RAK BESI GUDANG PABRIK RR-2000 is part of our super heavy-duty racking series, developed to handle extremely heavy loads and provide robust, high-capacity storage for modern warehouses.

Real-World Applications

The heavy duty racking system described above is versatile and finds applications in various industries:

- Manufacturing: Storing raw materials, work-in-progress items, and finished products efficiently.

- Logistics & Distribution: Optimizing storage in large distribution centers to improve order fulfillment and inventory management.

- Automotive Industry: Securely storing heavy automotive components and spare parts.

- Retail Warehousing: Managing high volumes of products in supermarkets and large retail stores.

- Industrial Manufacturing: Safely housing heavy machinery parts and components that require robust storage solutions.

By adopting our heavy duty racking system, companies can streamline their storage operations, reduce labor costs, and improve overall efficiency.

Tips for Maximizing the Use of Your Heavy Duty Racking System

To get the most out of your investment in a heavy duty racking system, consider the following best practices:

- Plan Your Warehouse Layout:

Develop a comprehensive plan that optimizes space usage and ensures clear pathways for material handling equipment. A well-thought-out layout minimizes downtime and increases productivity. - Professional Installation:

Ensure that your racks are installed by professionals who follow manufacturer guidelines. Proper installation is crucial to ensure the racks can support the intended load capacity safely. - Regular Inspections:

Schedule routine inspections to check for any signs of wear, corrosion, or structural damage. Timely maintenance is essential for preserving the integrity and safety of the racking system. - Training for Employees:

Provide thorough training for warehouse staff on the proper loading, unloading, and handling procedures. Educated employees are less likely to cause damage or overloading issues. - Maintain Cleanliness:

Keep the racks free from debris and dust that can contribute to wear and corrosion. Regular cleaning helps maintain the rack’s appearance and functionality. - Monitor Load Distribution:

Ensure that each level of the rack is loaded evenly. Uneven load distribution can compromise the structural integrity of the system and reduce its lifespan. - Plan for Future Expansion:

Choose a system that is modular and scalable so you can adjust the configuration as your storage needs evolve. A scalable system saves costs in the long run and adapts to growing business requirements.

The HEAVY DUTY RACK FOR STORAGE INDUSTRIAL WAREHOUSES is a crucial investment for any company looking to optimize its warehouse operations. With its robust construction, high load capacity, and flexible design, our heavy duty racking system provides a secure and efficient storage solution tailored for large industrial warehouses. By maximizing vertical space, improving inventory management, and ensuring a high level of safety, this system helps reduce operational costs and enhance productivity.

At RAJA RAK GUDANG INDONESIA, we bring over 12 years of industry experience and have earned the trust of more than 20,000 customers across Indonesia. Our extensive range of products, including more than 500 types of warehouse and display racks, is designed to meet the diverse needs of industrial clients. We serve major cities across Indonesia—from Jakarta to Surabaya, Bandung, Medan, and beyond—with professional installation and reliable delivery services.

If you’re ready to upgrade your warehouse storage with a system that offers both power and versatility, consider the RAK BESI GUDANG PABRIK UKURAN BESAR KAPASITAS 2 TON / LEVEL TIPE RR-2000. To receive a personalized quote, please provide the following information:

- Dimensions Required: Length, width, and height of the rack.

- Load Capacity per Level: Based on your specific storage requirements.

- Number of Shelving Layers Needed: How many levels you need.

Our expert team at RAJA RAK GUDANG INDONESIA is ready to assist you in designing, delivering, and installing the perfect heavy duty racking system tailored to your warehouse’s unique needs.

Contact Us Today!

Phone: 021-87786434 / 87786435 / 87786436

WhatsApp:

- Didin: 081288551012

- Idris: 081296786785

- Rahmat: 082184497726

Email: [email protected], [email protected], [email protected]

Website: RAJARAKGUDANG.CO.ID | RAKGUDANGHEAVYDUTY.COM

Office Address: Jl. Mastrip No. 09, Kel. Rambutan, Kec. Ciracas, East Jakarta, DKI Jakarta 13830 (Opposite Terminal Kampung Rambutan)

Invest in the best heavy duty racking system for your industrial warehouse today and experience the efficiency, safety, and durability that only a top-quality system can offer. Trust RAJA RAK GUDANG INDONESIA to provide the ultimate solution for your storage needs—your storage challenges are our solutions!

Thanks,

RAJARAKGUDANG.CO.ID | a Part of RAJA RAK INDONESIA